KBR Forward Operating Base Systems

Operation Desert Storm / Iraqi Freedom

Zirkle Fruit Company

Yakima, Washington

US Coast Guard Air Station

Coos Bay, Oregon

BioWillie - Willie Nelson

Carl's Corner, Texas

East Hampton Airport

East Hampton, New York

Rolls Royce Engine Test Facility

NASA Stennis Space Center

Siemens Turbine Generators

PDVSA - Venezuela

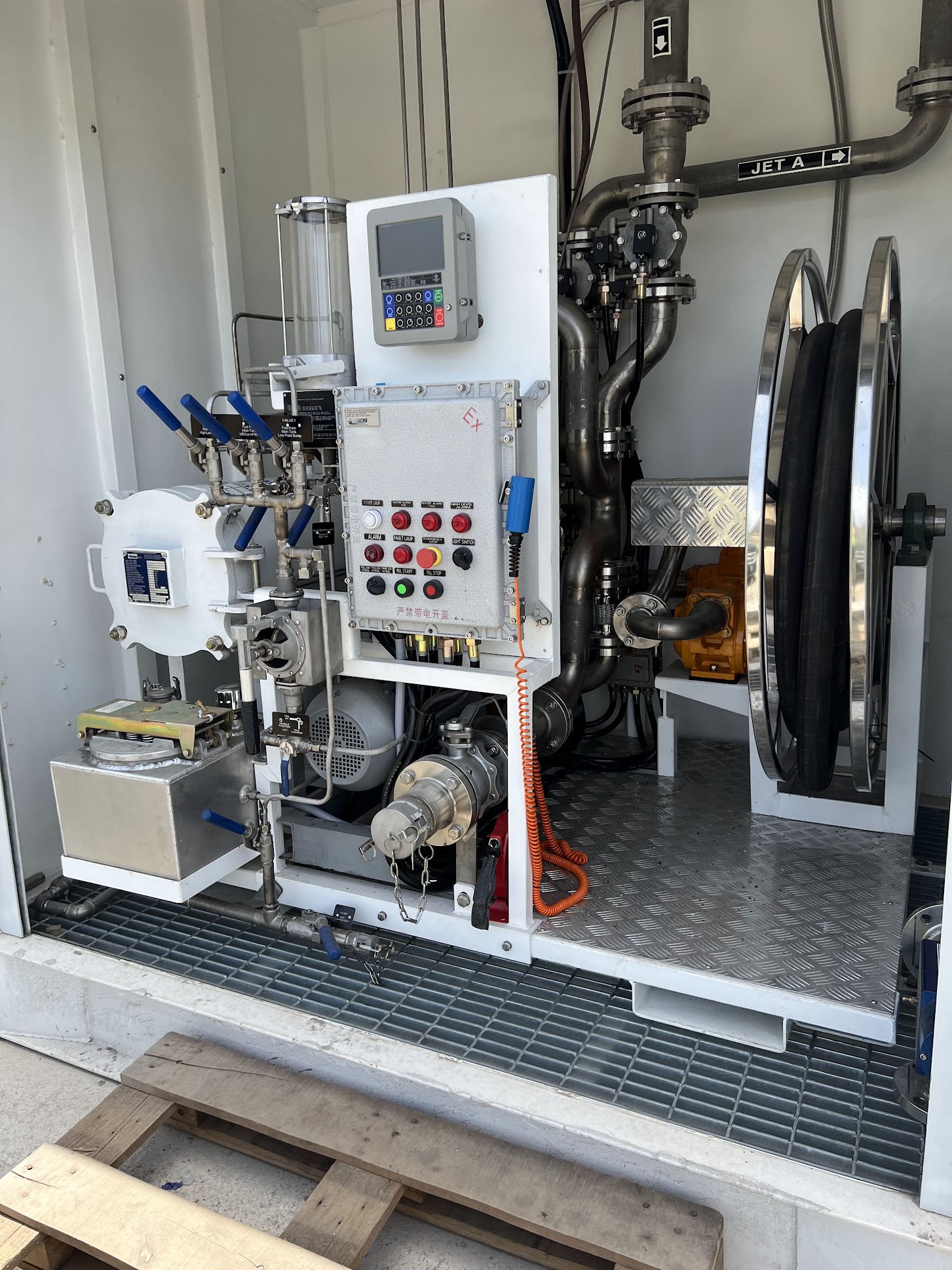

Providenciales International Airport

Turks & Caicos Islands

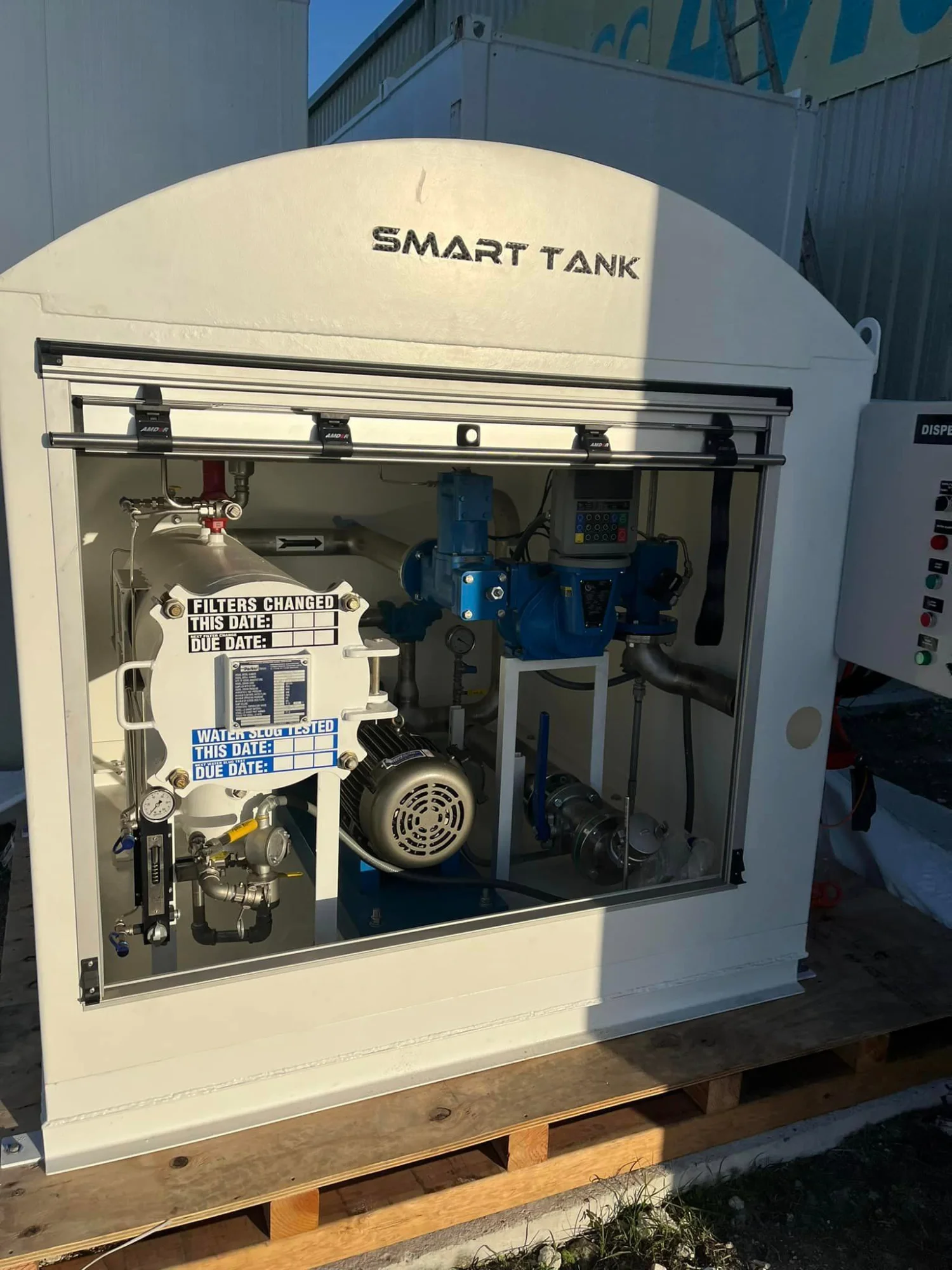

St. Eustatius (Statia)

Tearr Aviation - Caribbean

Hospital Helicopter Fueling

Joplin, Missouri